DTG vs DTF Printing Which is Better for T-Shirts

DTG vs DTF Printing:

Which is Better for T-Shirts?

If you’re looking into custom t-shirts, print-on-demand services, or starting your own apparel brand, you’ll quickly come across two popular printing methods: DTG (Direct-to-Garment) and DTF (Direct-to-Film). Both are modern technologies, both can produce high-quality shirts, and both are widely used in the custom clothing industry. But here’s the big question: which one is better?

This article is designed to give you a complete, easy-to-understand breakdown of DTG vs DTF printing. We’ll cover how each works, the pros and cons, print quality, durability, costs, myths, FAQs, and even real-world case studies. The goal is simple: by the end of this guide, you’ll know which printing method is best for your needs . whether you’re an entrepreneur, a designer, or just someone curious about custom shirts.

Introduction: Why This Question Matters

The t-shirt industry is booming. Millions of people every year buy custom shirts online. Brands, influencers, schools, sports teams, and entrepreneurs all want unique apparel. With this demand comes the need for printing methods that are fast, affordable, and high quality. That’s where DTG and DTF come in.

At first glance, these two methods may seem similar. Both can print colorful, detailed designs. Both are digital processes (no screen printing setup required). And both can be used for single orders or bulk runs. But under the hood, they’re quite different. And those differences affect the final look, feel, cost, and durability of the shirt.

Part 1: What is DTG Printing?

DTG stands for Direct-to-Garment. The name says it all. this method prints ink directly onto the fabric of the shirt. Imagine an inkjet printer, but instead of paper, you feed in a t-shirt. The printer sprays water-based ink directly onto the cotton fibers, and then the shirt is heat-pressed to cure the ink. The result? A soft, detailed print that feels like part of the fabric itself.

Here’s how the DTG process works step by step:

- Pretreatment: Dark or colored shirts are sprayed with a pretreatment solution. This helps the ink stick to the fabric and prevents colors from bleeding.

- Printing: The shirt is loaded into the DTG printer. The printer sprays the design directly onto the shirt with CMYK (cyan, magenta, yellow, black) inks.

- Heat Curing: After printing, the shirt is pressed with heat to cure the ink and lock it into the fibers.

The result is a smooth, breathable print. Since the ink is absorbed into the fabric, DTG prints don’t feel heavy. They’re excellent for designs with gradients, photos, or lots of color details.

Part 2: What is DTF Printing?

DTF stands for Direct-to-Film. This method works differently. Instead of printing directly on the shirt, the design is printed onto a clear film using special inks. Then, a powdered adhesive is applied to the design. The film is heated so the powder melts and bonds to the ink. Finally, the film is placed on the shirt and heat-pressed. The design transfers from the film onto the shirt, leaving a durable print.

Step-by-step DTF process:

- Printing on Film: The design is printed onto PET film using CMYK inks plus a white underbase.

- Adhesive Powder: A fine adhesive powder is applied to the wet ink. This powder will bond the ink to the fabric later.

- Curing the Film: The film with ink and powder is heated, which melts the adhesive and prepares it for transfer.

- Heat Transfer: The film is pressed onto the shirt with a heat press. The adhesive and ink bond to the fabric, and the film is peeled away.

The result is a bright, vivid print that sits on top of the fabric. Unlike DTG, the ink doesn’t soak into the fibers — instead, it forms a thin layer. This makes DTF more versatile across different fabrics, but also gives the print a slightly different feel.

Part 3: Key Differences Between DTG and DTF

Let’s compare the two head-to-head:

- Process: DTG = ink goes straight into the shirt. DTF = ink goes on film, then transferred.

- Fabric Compatibility: DTG works best on 100% cotton. DTF works on cotton, polyester, blends, nylon, and more.

- Print Feel: DTG feels smooth and soft, like part of the shirt. DTF feels like a thin plastic layer on top.

- Durability: DTF usually lasts longer in wash tests. DTG can fade faster if not washed carefully.

- Color Vibrancy: DTF tends to look brighter, while DTG looks softer and more natural.

- Setup Time: DTG is easier for single prints. DTF requires powder and transfer steps.

Part 4: Pros and Cons of DTG Printing

Pros

- Soft, breathable prints that feel like part of the fabric.

- Excellent for complex designs, gradients, and photographs.

- No setup costs — perfect for print-on-demand.

- Environmentally friendly inks (water-based).

Cons

- Works best only on cotton struggles on polyester.

- Prints may fade faster if washed incorrectly.

- Not ideal for bulk orders due to slower speed.

- Requires pretreatment for dark fabrics.

Part 5: Pros and Cons of DTF Printing

Pros

- Works on almost any fabric, not just cotton.

- Vibrant, bold colors with sharp edges.

- Very durable, resists washing and cracking.

- Better for small text and sharp logos.

- Transfers can be printed ahead and stored.

Cons

- Print feels less natural (plastic-like layer).

- Less breathable for large designs.

- Not as eco-friendly (film and adhesive waste).

- More steps in the process, so not as quick for one-offs.

Part 6: Print Quality Comparison

DTG is known for smooth, fabric-like prints, perfect for photo-style designs. DTF is known for sharp, vibrant designs, perfect for logos and bold artwork. Which one looks better depends on your design. If you want realism and softness, DTG wins. If you want boldness and brightness, DTF wins.

Part 7: Durability and Wash Test

In wash tests, DTF prints tend to outlast DTG. Because DTF sits on top of the fabric, it doesn’t fade as fast. DTG, however, can last long too if cared for properly. Washing inside-out, in cold water, and air-drying extends DTG lifespan.

Part 8: Fabric Compatibility

DTG: Best on 100% cotton. DTF: Works on cotton, polyester, blends, nylon, spandex, and even leather. If you plan to print on sports jerseys or polyester hoodies, DTF is the clear choice.

Part 9: Cost and Business Impact

DTG printers are expensive ($15,000+), but POD platforms absorb that cost. If you run your own shop, DTG is cost-effective for one-offs. DTF printers are cheaper to start ($3,000–$7,000), but require film, powder, and heat presses. For bulk orders, DTF often ends up cheaper per print.

Part 10: Eco-Friendliness

DTG uses water-based inks, which are more eco-friendly. However, pretreatment chemicals add some environmental impact. DTF uses plastic films and adhesive powders, which create more waste. If sustainability is important, DTG is the greener option.

Part 11: Which Customers Prefer Which?

Streetwear fans often love the boldness of DTF. Artists and illustrators love the softness of DTG. Corporate and sports buyers lean toward DTF for logos on polyester gear. Casual t-shirt buyers usually don’t notice much difference. both methods produce quality shirts.

Part 12: Common Myths

- “DTF is always better” False. Depends on design and use case.

- “DTG always fades” Not true if washed correctly.

- “DTF feels heavy” True for big designs, but small logos feel fine.

- “DTG can’t print white” False, modern DTG printers use white ink with pretreatment.

Part 13: FAQs

Does DTG work on dark shirts? Yes, with pretreatment and white ink. Does DTF crack? If applied properly, it lasts very long, though large prints can stiffen. Which is cheaper? For single prints, DTG. For bulk, DTF. Can I do DTG at home? Machines are expensive, so usually not. Can I order DTF transfers separately? Yes, many suppliers sell pre-printed transfers you can press later.

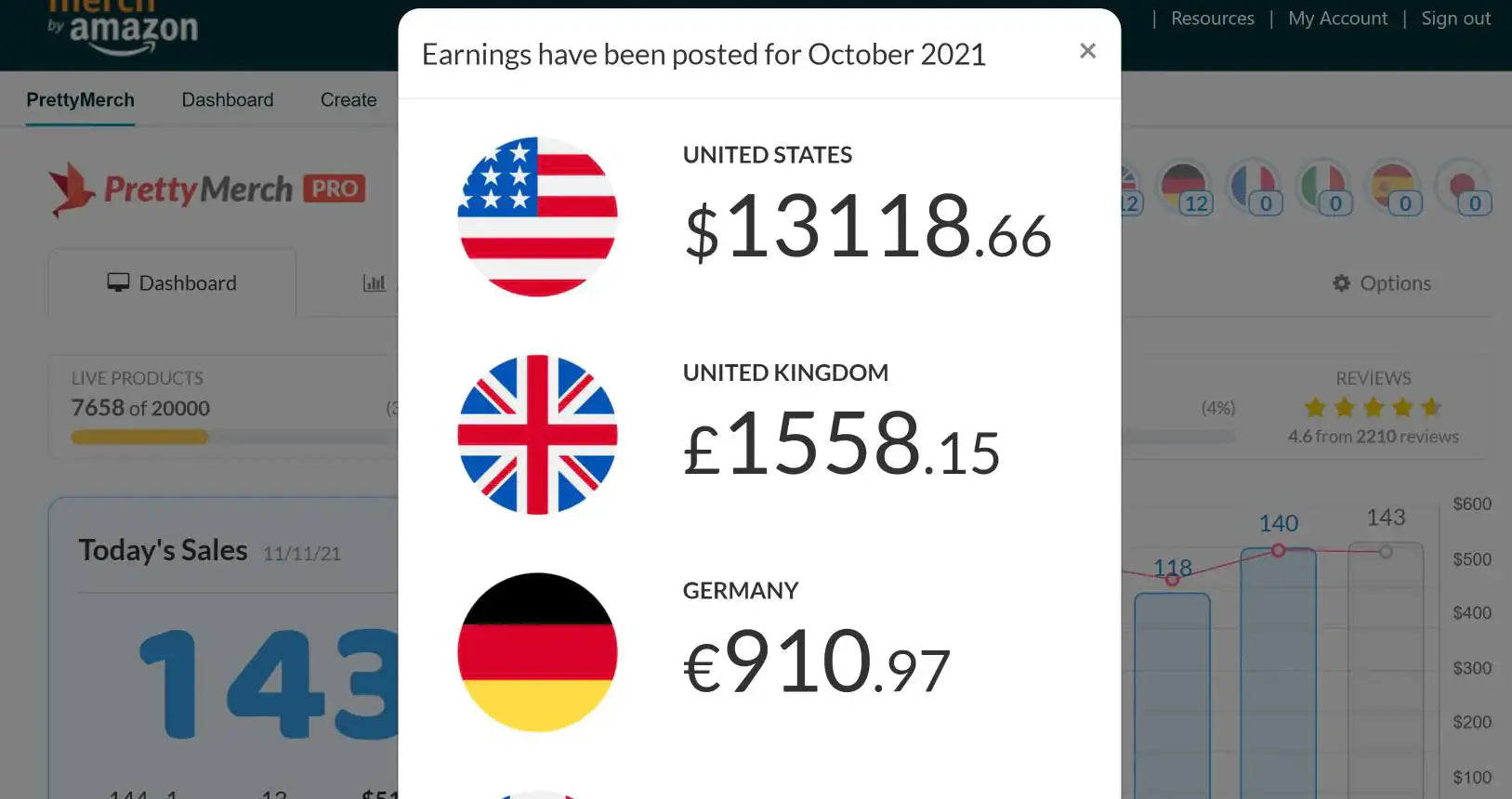

Part 14: Real-World Case Studies

Amazon Merch on Demand: Uses DTG because it’s perfect for POD. Local Sports Teams: Prefer DTF for uniforms on polyester. Hybrid Shops: Many shops now offer both DTG for cotton tees, DTF for hoodies and polyester gear.

Part 15: Final Verdict

So, which is better DTG or DTF? The answer is: it depends on your needs.

- Choose DTG if you sell on POD platforms, want ultra-soft prints, or mainly print on cotton shirts.

- Choose DTF if you need durability, bright colors, or plan to print on a wide range of fabrics.

- Best Strategy: Use DTG for POD and one-offs, add DTF for bulk or specialty orders.

Both methods are powerful tools. The key is not choosing one forever, but knowing when to use each. With DTG and DTF together, you can serve almost any customer and grow your apparel business without limits.

Written by MerchCrafter™ . Helping entrepreneurs succeed in print-on-demand and custom apparel.